Welcome! On this post, I will be updating my experiences in the Aalto Design Factory PdP course and what skills I have learned, which could be adapted to the HAMK Design Factory.

My name is Markku Mikkonen and I work in HAMK Design Factory as our Technical Expert. More information about my background, can be read from here.

PdP introduction

For those new to the PdP concept, it means “Product development Project”, where students from different backgrounds work together in groups towards researching, designing, developing and prototyping ideas, which have been brought in by the project sponsors. The projects in Aalto are about eight months long during of which students can attend to special workshops, which can help the development of their projects. For example, creative techniques or electronic workshops.

Our team consists overall of nine members, which of five members are from Aalto DF (me included) and the other four from Porto DF.

Presentations and battle

During the first couple of weeks in the PdP course, everyone was introduced to the Aalto main staff members, DF building, older PdP projects with their outcomes, details of the upcoming courses and some fun group projects. After these presentations the project manager candidates (PM:s) presented themselves and what projects they were interested. After the presentations, everyone was divided into groups with the project manager candidates.

After the groups were formed, began the actual “battle” for the projects. Before this “battle”, each project had their sponsors present their idea request in detail, which helped everyone to get a better understanding of what would be requested from them. There were a lot of projects available and our group was interested in many of the available ideas, but we were dead set on getting the Airbus project. Finally, when all the project ideas were presented, and the groups had decided on their top projects, the PM:s were left to “battle” between themselves on, which group gets which project. All I can say, is that I heard the “battle” was fierce, but our groups PM got out victorious Meaning that we got our top pick, being the Airbus project.

Our Project

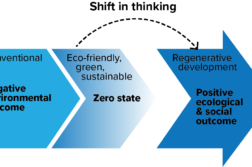

The Airbus project idea was based on the concept of creating a Design Factory type of workspace into the industry company. At this stage, this was all the info we got from our sponsor and he also added, that we get free hands on the idealization and research of the prototype. This was somewhat difficult to work with because we didn’t have any limitations or more info on the wished idea would’ve been useful for gathering more specific kind of information. Our group mainly ended up researching co-creation, innovation spaces and what subjects develop these types of ideas.

During this researching phase, we also attended extra workshops. Both of these workshops were optional but they were very informative and experience wise rewarding. First being about creative thinking, which included theory-based ideas, to develop a person’s way of thinking outside of the box and how to brainstorm ideas with others efficiently. These theory ideas helped our group to find new ways to work together with our project and develop our ideas, which also helped us develop our projects main question even further.

Workshops

The second workshop was more for HAMK DF (HDF) experience gain than to help our team´s project because we’re not certain that what kind of prototype we would creating at the end of Airbus design factory, (ADF), but we doubt that it will be anything concrete. My goal for the electronic workshop was to learn more basic information and techniques, when working with components and Arduino programming. This way I can share the same type of information in HDF PdP course, which would start at the beginning of 2020.

I was nominated as our group’s safety and communication officer. This was mainly due to me having a wide background working with different materials and for my own interest of being the communication link between us, our Porto team and other possible future partners. Our PM is the communication link to our sponsor. This way, by having certain team members working as communication officers, we avoid having too many different people contacting the same person and information flow stays stable without communication gaps.

At the beginning of December, we got the opportunity to visit the Tech Center ZAL, located in Hamburg, where our sponsors company is partially located in. More information on my visit to Hamburg can be read from here.

To be continued in January 2020…

-Markku

Discussion3 Comments

Pingback: Markku PDP trip to Hamburg - Design Factory

Pingback: Lessons learned from product development project - Design Factory %

Pingback: Design Factory PDP during quarantine - Design Factory