Part-time engineering students Arto Pöyhönen and Jukka Eronen share their experiences on how group work is implemented when you study remotely and what a real-life product design task looks like.

Background

We are studying mechanical engineering in Finnish (konetekniikka) at HAMK and our studies have been implemented as part-time studies. One of us is starting his third year of studies and the other one starts their fourth year. For both of us, part-time studies were the only possible way to study engineering and it was great that HAMK offered education in our field as a part-time implementation. This has made it possible to flexibly fit studies into our schedules, living in another town and going to work.

Note: Part-time study option is only available in the Finnish engineering degrees.

Preamble

Many courses in our studies include group work, which consists of several elements, from forming groups to sharing tasks and reaching a common goal to complete the assigned tasks. Group work is implemented both in the technical subjects and in linguistic studies. The aim of these is to create a basis for the knowledge needed in working life for working with various projects.

Our first course where we got to design based on a client’s brief was Product Design. The aim of the course was to design a new waste sorting concept for a real client company. The project was very interesting from the outset because it allowed us to design and develop something new.

The project was divided into eight groups and modules, with seven groups designing their “own” module and one group designing the whole sorting system. Seven groups were tasked with designing and calculating a cost-effective module and one group designed all the modules in a cursory way to give the client a good overview of what could be taken forward. The initial plan was for all groups to design three to four different options, from which, based on customer feedback, each group would go on to refine their plan into one final version. Each group’s proposal was to include an indicative cost estimate and a list of components. The task was also to benchmark the products on the market.

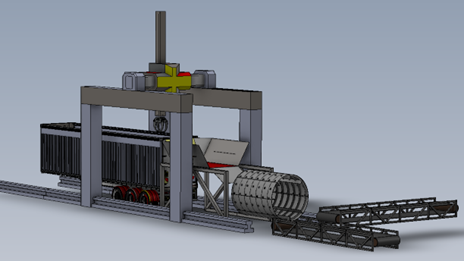

Waste feed system

The task was to design something new and better so there was room for imagination.

Arto’s team started to design the outline of a whole waste treatment system with specific concepts, taking into account the current problem areas and efficiency. What made this interesting was that the concept required inventing something new and/or applying the old in a new way.

All units were designed as long-life devices and kept simple to ensure good reliability. The main advantage of the new concept over the old one was considered to be its length, which was significantly reduced. This will help to keep costs reasonable and facilitate possible relocation.

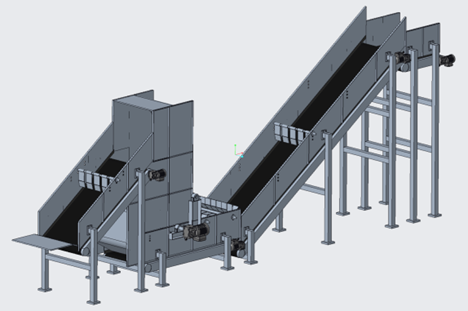

Conveyor

Jukka’s team’s mission was to design a conveyor, which had to have a unit corresponding to a free fall of two meters in height and it had to produce as even a flow of material as possible from the input point of the sorting line to the next module. The purpose of the unit corresponding to the free fall of the conveyor was to break and spread any clumps stuck to each other and thus produce a steady flow of material.

The picture below shows the basic layout of the conveyor module with all its major components. In the left you have the feeder for the conveyor followed by the free-fall unit. From there the waste flow continues to the main lifting unit below built-in flow-spreading equalizers. From the right end the waste flow is being fed to the next unit of the waste separator system.

Commonly available, high quality standard components were used as much as possible as conveyor components. This way the maintenance of the conveyor would be successful without the need for custom-made parts, which enables smooth and on-schedule maintenance.

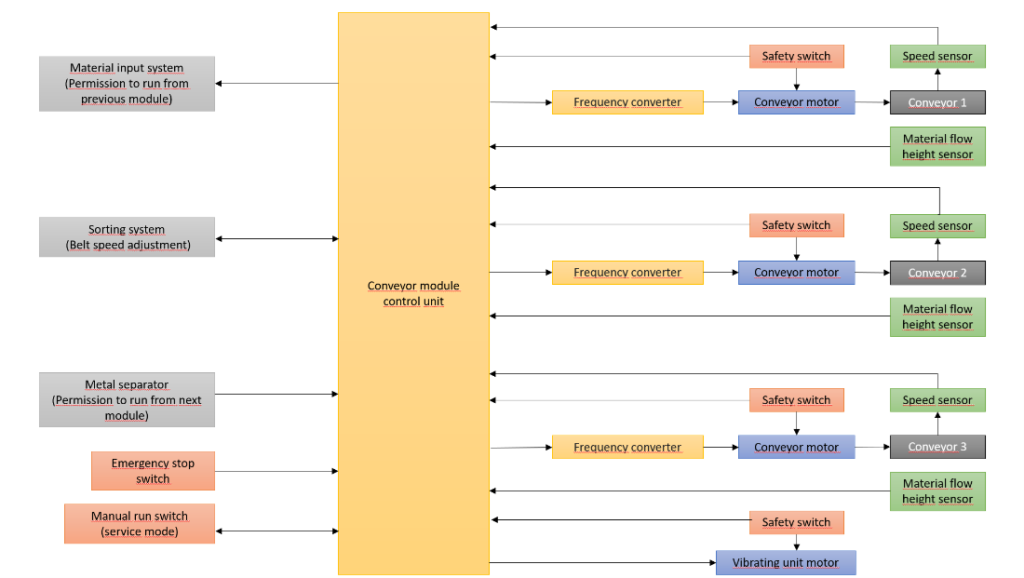

Our group divided the task into sub-areas, of which each team member developed based on the group’s feedback. This collective vision proved to be a good asset in this task as well and it refined our concept into a functioning entity. Part of the assignment was to design the control system in such a way that the safety requirements set by authorities and standards of such a system were met, and the offer requests could be sent to the software suppliers for evaluation.

Guided by our tutor’s feedback, the final concept began to take shape into a functional module that could be integrated as part of a functional demolition waste sorting unit.

This project was not our group’s first collaborative project. Our group, formed in the first year of studies, has proven to be functional teams in this year’s tasks as well. The cooperation went well even though we live in different places. We didn’t have time to get the view of the client of the project as feedback, but our project received good tutoring from the leader of our course. Overall, the assignment was interesting and with good cooperation we were able to create a working model.

Closing words

One of the most important things in working as a group, besides the result, is to find and utilize the strengths of each member of the group. When each member does their part according to their strengths, the result will be better than what each member of the group could have reached alone. This was the case this time as well.

Authors

Arto Pöyhönen & Jukka Eronen, part-time mechanical engineering students