Reverse Engineering is widely used in mechanical, automotive, aerospace, medical fields. Reverse Engineering perform a key role in development of product cycle, because it affects on product design, production and quality management.

What is Reverse Engineering?

Reverse Engineering is the process of extracting design information from anything made and reproducing anything based on this information. It is the technology of creating digitized design data to be used for creation of products from a real object.

Reverse Engineering is used in

- Duplicating a product for which no documents or CAD data exists

- Manufacturing of a new product based on an existing product

- Customizing products fitted for human body

- Reconstructing damaged objects

- Using digitized shape information for animation

- Manufacturing products in the medical or dental fields

- Analyzing design elements from competitors’ products

The process involves

- Measuring the object, that allow to get exact measurements and surface shape of an object

- Reconstructing it as 3D model for production using CAD (Computer-aided design) software

- Bring the existing physical geometry into digital product development environment (Computer-aided manufacturing)

- Make a digital record of product

- Analyze how product works with simulation software

- Estimate cost of production

What is limitation and important features of Reverse Engineering?

- Geometry

Complex geometry increases the time for measuring and designing.

- Requirements

For what purpose customer needs this object? What is important geometry features? Answer for these questions helps to choose the strategy of Reverse Engineering.

Strategy of Reverse Engineering

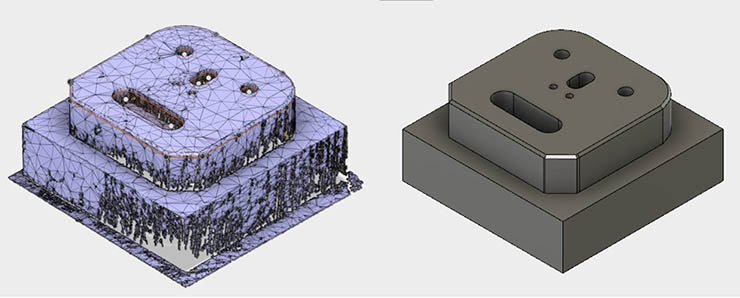

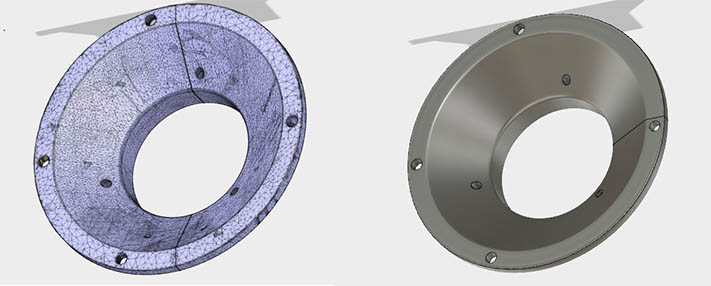

- Mesh modeling

Main purpose is creating an optimized mesh from 3D scan data to be used as reference prototype.

- Parametric Feature Modeling

Main purpose is creating a 3D feature model based on mesh from 3D scan data. The created features can be reused, redefined, modified and translated by controlling parameters.

- Fitting surface modeling

Main purpose is creating a 3D freeform model based on the optimized mesh from 3D scan data.

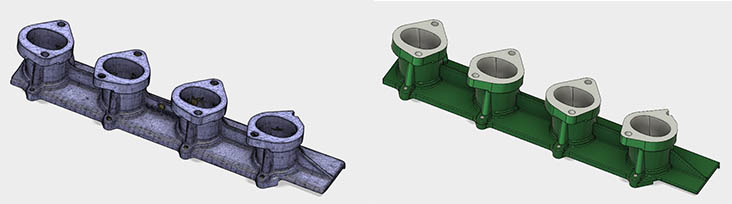

Example of Reverse Engineering cycle

Real object of Manifold for Sarlin Racing Team. It is a case of manufacturing of a new product based on an existing product.

First, mesh modeling was done.

Then Parametric Feature modeling was made. The object was modified and redesign by the way, that all functions of part is made according requirements of production method and utilization. Finally, production was made using CNC (computer numerical control) machine.

Conclusion

Reverse Engineering has become a popular method for creation a 3D models of existing objects to be used in CAM, CAD, CAE (Computer-aided engineering). It can benefit in bug fixing, improving of documentation shortcoming, product analysis and money saving.