Having a hands-on experience with tools and machines that I have been admiring for years and being able to use that equipment freely inside a lab was a very nice complement to my theoretical background. It allowed me to not only learn about the tools, but also re-evaluate my sense of complexity about the programming and operation of robotic arms and computer vision systems.

At a first glance, the collaborative robot and all the tools and sensors surrounding its environment transmitted me a sense of complexity and an impression that I would have a lot of hard work ahead to learn the programming routines, software and hardware and detailed characteristics of that robotic system.

In reality, that first impression was far away from the truth. After an online training of about 90 minutes provided by the manufacturer, I was able to program the basic features of the robot, configure hardware and software of sensors and within in a few hours I was not just moving the robot arm around its work space, but performing elaborated palletizing and depalletizing tasks. At the end of that same day, actively sorting parts based on its dimensions and configuring safety parameters to share the robot working area without risks were no secret to me anymore.

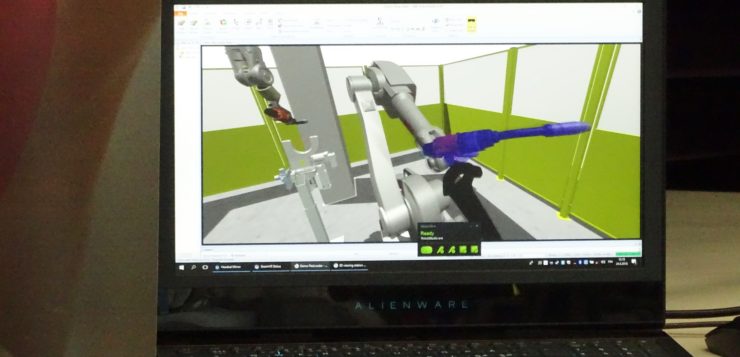

Going further into the possibilities offered by this robotic arm system were the computer vision equipment built to accurately ”look,” measure and position inside a virtual space, the parts that the robot should manipulate. The vision system manufacturer also provided a comprehensive guide to the software configuration through a web-based graphical environment. As a result, I was able to set up cameras, spaces and objects successfully, and in about an hour and I could perform a basic automated pick and place task. The knowledge acquired through this guided configuration made me understand this vision systems basics and enabled me to go even further on its setup processes, creating more elaborated tasks throughout the following days.

The learning experience I had at the robotics lab made me think and reconsider the barrier that complexity biases often build between high-tech tools usage and the real ability to understand, learn, use and develop solutions using advanced equipment. Instead of just programming a collaborative robotic arm, I could also experience an increase on my motivation to learn about even more complex systems. Other engineering students who could experience the same barrier breakdown may begin to rely even more on their ability of quick learning and in their ability of using more and more complex tools in the course of their careers.

Arturo Manzoli

Exchange student from Federal Institute of Technology, Florianopolis, Brazil