Do you know what kind of work is required before your local market roof or your neighbour’s machine shop can be built? Have you been thinking that someone will do complex research and development work, so you can safely enter to the building?

There are few proven construction materials, such as concrete, steel or timber, that are found in every building around us. Cold-formed steel elements have an advantage in certain cases over other construction materials due to their versatility, cost-effectiveness, and ease of installation. However, the design of such structures is more complex, making it important for producers to conduct extensive experimental studies to ensure the safety of inhabitants.

There are predefined design rules on how to design structures, so that they are safe and reliable. But, when designing something new, often there are no rules on how to specify what would be the maximum load for a certain type of structure to endure harsh environmental and accidental loads, such as wind or snow. For this instance, complicated research, combined with testing must be conducted, as it is the case with a project that HAMK Tech’s Steel Structures Research Group is tasked with by a company that specializes in the construction of buildings using cold-formed steel arch elements.

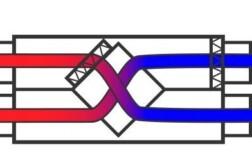

The steel element is in the shape of an arch with complex cross-section strengthened by corrugations in more than one direction, making the design calculations of the load-bearing capacity a challenging mathematical task.

This research project can lead to improved safety and efficiency in the construction process. Understanding the behavior under various loading conditions could lead to new design possibilities and opens the way for innovation. It is crucial for companies to stay competitive and ensure their structures’ safety, stability, and longevity.

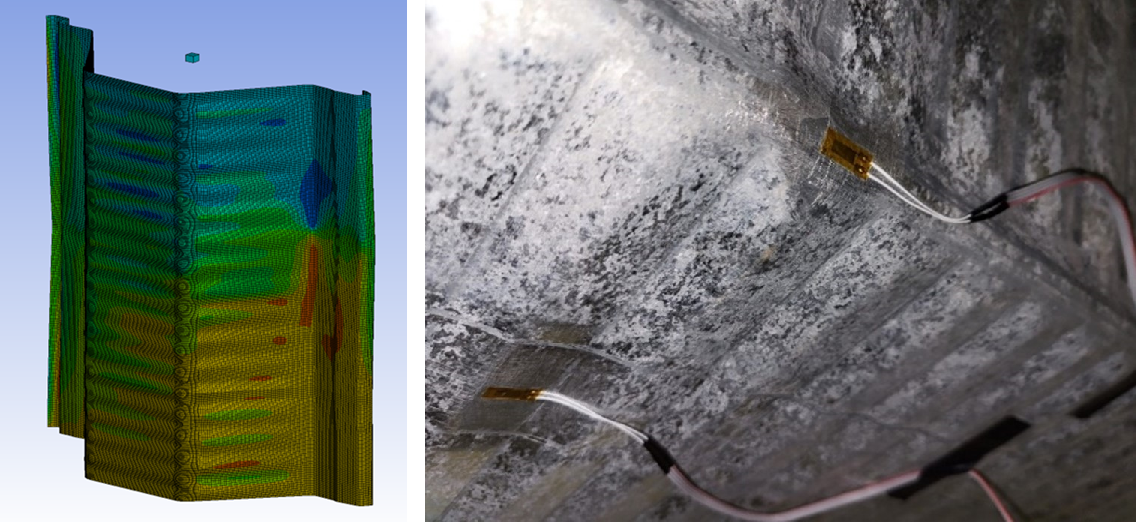

The researchers at HAMK Tech Research Unit are working on the design and development of experimental methods that combined with Finite Element Methods (FEM) produce design guidelines including critical design formulas. FEM is a mathematical technique used by engineers to understand how different structures or materials will behave under specific conditions. It is a method of breaking down complex objects into tiny, simple pieces and then using mathematics to solve how these pieces interact with each other. For example, it can be used to predict how an element will behave under heavy snowfall or high winds.

Physical testing consists of more than 100 loading tests carried out at the Steel Structures Laboratory located at HAMK Campus in Hämeenlinna. The research team created unique testing setups that would produce reliable results, utilizing creativity and a deep understanding of the underlying physical principles. As one part of the team is working in the lab, others are developing complex numerical models of the same elements to be analysed and tested by a computer in the same loading configuration.

In order to be as precise as possible in building a reliable model, sample elements were scanned digitally at another HAMK Tech facility using advanced 3D scanning technologies. Data collection points for analysis include deformation and displacement sensors, and cylinder force. Utmost importance is given to teamwork and careful coordination. Each step forward consists of the exchange of information on a weekly basis of testing results and computer simulations. The project is also part of three master’s theses, as well as student trainees from Construction Engineering degree program at HAMK.

In order to be as precise as possible in building a reliable model, sample elements were scanned digitally at another HAMK Tech facility using advanced 3D scanning technologies. Data collection points for analysis include deformation and displacement sensors, and cylinder force. Utmost importance is given to teamwork and careful coordination. Each step forward consists of the exchange of information on a weekly basis of testing results and computer simulations. The project is also part of three master’s theses, as well as student trainees from Construction Engineering degree program at HAMK.

Author:

Georgi Georgiev, Research Assistant, HAMK Tech Research Unit, Steel Structures Reseach Group

Discussion2 kommenttia

It is good to know that the HAMK continues to research K-Span structures. The works of Al-Maisari and Nwankwo contain great experimental and numerical studies.

I am looking forward to knowing the results of the bending test that is shown in this article.

We currently carry out similar research at the International University of Catalonia, Barcelona.

Networking and collaboration within the research community can foster new ideas and mutually beneficial partnerships.

Good luck with your research!

It is good to know that the research on the K-span profiles continues in the HAMK after the great works of Al-Maisari and Nwankwo.

We currently work in a similar field at the International University of Catalonia, Barcelona.

Good luck with your research!